The high-performance carbon that Jikantechno Inc. manufactures from agricultural residues can be found in many products we use every day, such as lithium-ion batteries, cosmetics, and car tires. Reaching commercial viability was a journey of trials and tribulations, says Takahiro Kinoshita, CEO of Jikantechno.

Please tell us about Jikantechno’s business.

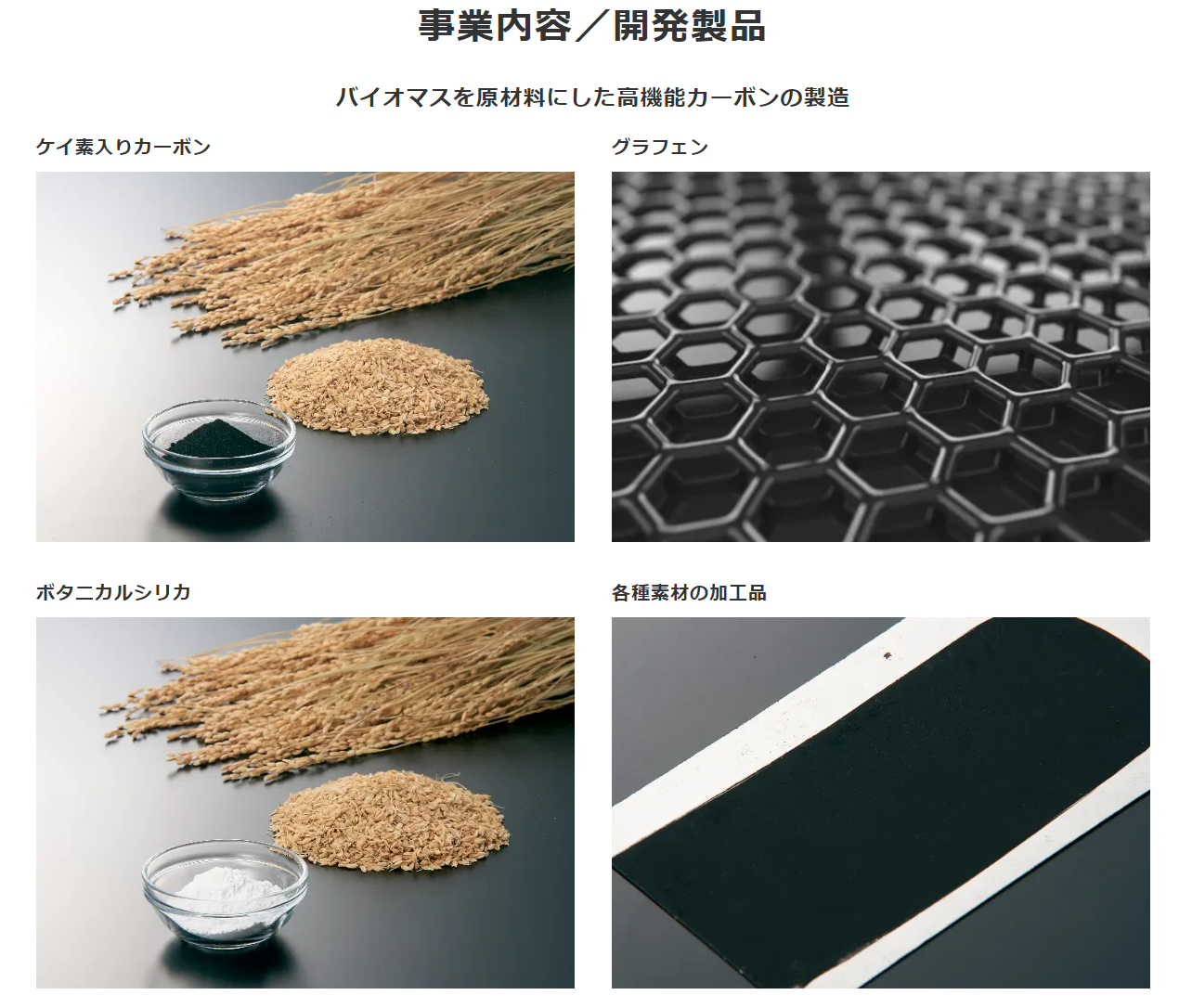

Japan generates about two million tons of rice husks every year, and the waste disposal fees take a toll on rice growers who shoulder the costs. Jikantechno is the first company in the world to create high-quality, fair-priced carbon materials out of agricultural residues such as rice husks. Other residual output such as sake lees, malt cakes from beer production, and cacao seed coatings from chocolates are also raw materials for us.

Carbon materials include silica which is used in semiconductors, and carbon and graphene, which are used in lithium-ion battery electrodes. These carbon materials are often made from minerals such as quartz and graphite. However, today, we face a shortage of raw minerals necessary for battery electrodes, and CO2 emissions during production have also become an issue. Further, as China, a producer of these mineral resources, curbs its exports, the outlook remains uncertain.

When we manufacture one of our products, Rice Silica™, from agricultural residue, the only CO2 emitted is the CO2 that the rice plants absorbed during photosynthesis. So, there is no additional discharge, and it is carbon neutral. Wastes from a primary industry are turned into high-value-added ingredients for a secondary industry, generating revenue for farmers and agricultural corporations.

Our technologies have low environmental impact and enable us to tackle various global issues such as food shortages and energy crises.

Please tell us about Jikantechno’s history and current projects.

Jikantechno was established in 2016. Our original goal as a company was to apply for a patent and utility model registration of a battery. In the process, we explored developing plant-based carbon from rice husks; this is how the business began.

With help from university professors, practical implementation began to look feasible around 2018. However, few people showed any interest in our work.

That all changed with COP26 (the 26th United Nations Climate Change Conference), held in the UK in 2021. In this meeting, Japan announced to target a 46% reduction of carbon dioxide emissions within the 2030s and to target “net zero” emissions” by 2050.

With these targets in mind, government authorities began considering carbon pricing programs, and companies had to react accordingly. Inquiries increased around this time, and many global companies are contacting us today.

One of our more recent projects is implementing a technology that nurtures vegetables. This technology involves placing a manufacturing site near agricultural land and using the heat and emissions from the site to boost plant growth. While plastic greenhouses are usually heated with fuel oil, we use waste heat from manufacturing Rice Silica™ to heat the greenhouse and use the emitted CO2 to assist the growth of the vegetables.

As a result, CO2 emissions are even less than zero, and vegetable yields also increase. The technology is a boon for farmers because it allows them to reduce fuel expenses and gain additional revenues from selling silica.

Plastic greenhouses are warmed with the heat generated when manufacturing Rice Silica™ from rice husks, and the emitted CO2 nourishes the tomato crop, increasing yield (From the home page of Tomato Land Iwaki).

What’s next for Jikantechno?

In May 2024, we participated in Europe’s largest innovation exhibit, VIVA TECHNOLOGY 2024, in Paris. We were finalists of the LVMH Moët Hennessy Louis Vuitton Innovation Award and exhibited at the LVMH booth.

Over 1,500 candidates from 89 countries around the world applied for this award. This year, two companies from Japan were selected for the first time. Jikantechno was selected as a company that manufactures sustainable, low environmental impact cosmetics ingredients. After the exhibit, we also participated in a new program at STATION F, a startup facility in Paris.

We are looking forward to maximizing these opportunities with everything we have.

Jikantechno will exhibit at the 2025 Osaka-Kansai Expo as a startup company aiming to achieve carbon neutrality.